scratch test metal|what is scratch testing : traders Scratch the piece to be tested over the surface of the black stone provided, press well so as to leave a visible deposit, preferably a line of one to one-half inches long. Please note: For the most accurate testing it is recommended that the user becomes familiar with comparative testing using standard gold testing . See more Resultado da 15,000+ FREE Online Slots Games to Play - Play free slot machines from top providers. Play with no download, no deposit, or registration!

{plog:ftitle_list}

19 de mai. de 2022 · Choose the ones that are more relevant to you, your interests, and the specific job ahead of time. Then write them down — either on a piece of paper or on your phone — and glance at them right .

Scratch the piece to be tested over the surface of the black stone provided, press well so as to leave a visible deposit, preferably a line of one to one-half inches long. Please note: For the most accurate testing it is recommended that the user becomes familiar with comparative testing using standard gold testing . See moreScratch the piece to be tested over the surface of the black stone provided. Press well so as to leave a LARGE AND THICK visible deposit, preferably a line of one . See moreScratch the piece to be tested over the surface of the black stone provided, press well so as to leave a large and thick visible deposit, preferably a line of one to one . See moreWhatever purity you find, Shor's aqua regia refining system, the AR3G, can meet all of you gold and platinum refining needs See more

In this blog post, we will delve into the different methods and steps involved in performing scratch resistance tests, ensuring accurate and reliable results. What is a Scratch .

The hardness test developed by Friedrich Mohs was the first known test to assess resistance of a material to scratching. It is a very simple but inexact comparative test. Perhaps its simplicity has enabled it to become the most .Scratch testing is a simple and rapid method of characterizing coatings, but results obtained are influenced by various factors such as coating thickness, substrate mechanical properties, .

Scratch hardness testing uses a sharp object to measure how easily a surface is scratched. It can be used to test a wide range of materials and coatings and is used to determine how resistant . Testing for Platinum and White Gold. Scratch the piece to be tested over the surface of the black stone provided, press well so as to leave a large and thick visible deposit, preferably a line of one to one-half inches long. . 1.1 This test method covers laboratory procedures for determining the scratch hardness of the surfaces of solid materials. Within certain limitations, as described in this . To learn How To Test Gold Metal Shavings, follow this link. Inside Metal Scratch Test. For this method of testing gold that you suspect of being 10 karat value gold or less, you will test it much the same way you test gold non .

what is scratch testing

In many cases, the scratch test has now become accepted as a versatile tool for assessing the mechanical integrity of a surface, whether bulk or coated, and has found . It also doesn't tarnish and is denser than other precious metals. To see if your piece is platinum, first look for a stamp, or hallmark. If you can't find one or aren't sure what it means, . Indentation and scratch test methods offer alternative solutions in these cases. For the indentation method, Lawn et al. [9] proposed an indentation test method to evaluate the fracture toughness of quasi-brittle materials based on the critical fracture stress. Murty et al. [10] obtained the critical indentation depth of the quasi-brittle materials. . Byun et al. [11] proposed .

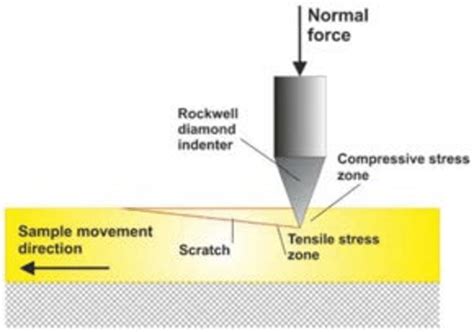

For many people, the most difficult part of this test is next: You need to stay still long enough (usually about 20 minutes) to give the skin time to react. Your skin might tickle or itch during this time, but you won't be allowed to scratch it. At the end of the waiting time, your doctor will examine each needle scratch for redness or swelling. An experimental and numerical study of the scratch test performed on metals and polymers was conducted. The materials tested, being both metallic and polymeric, were related to the well known Johnson’s parameter, often used to correlate indentation experiments. The aim was to determine whether it was possible to use the numerical approach .Mohs hardness test: When conducting the test, place the unknown specimen on a table top and firmly hold it in place with one hand. Then place a point of the reference specimen against a flat, unmarked surface of the unknown specimen. Press the reference specimen firmly against the unknown, and deliberately drag it across the flat surface while pressing firmly. Scratch test was performed by a scratch tester with a diamond indenter of 10-μm radius and cone angle 90°, applying a constant load of 500mN, and 2-mm-long scratches were made. The scratch marks were studied under 3D laser measuring microscope and cross-section profiles at approximately 0.5mm, 1.0mm, and 1.5mm from the starting point were .

Inside Metal Scratch Test. For this method of testing gold that you suspect of being 10 karat value gold or less, you will test it much the same way you test gold non-destructively with the scratch test. The only difference is that you will first cut the metal of the unknown gold piece and open it so you can scratch the metal inside the piece .

Hardness Test: The hardness test (commonly referred to as the Rockwell Hardness Test) looks at the strength of a metal against a material trying to imprint against it. Each metal has a specific hardness number assigned to it, which corresponds to the level of impression. This makes the hardness test one of the most accurate metal identifiers.

Steel: A common metal in tools and machinery, steel has a hardness of approximately 4-4.5 and thus cannot scratch a diamond. Titanium: Known for its strength and low density, . Scratch Test: As mentioned above, a real .Minimum Thicknesses for the Rockwell Hardness Test. Since the Rockwell test needs to make an indent in the test piece, there’s a minimum thickness associated with the test. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece.

water vapor permeability tester factories

Scratch Test Titanium, Stainless steel, Ceramic, Extra Hard Coated stainless steel, Bronze Comparison Which is best?Please don't forget to like and subscribe.Scratch Test. A simple scratch test can also help you identify brass. Take an inconspicuous or hidden area of your metal object and lightly scratch it with a knife or another sharp object. If the scratched area reveals a shiny yellow scratch, it’s likely solid brass. Be cautious not to damage valuable or antique items during this test. Buy an acid scratch test kit to verify platinum jewelry. If you can't find any marks on your jewelry, or you aren't sure what they mean, buy an acid scratch test online or at a jewelry store. Acid scratch test kits come with a scratch stone and bottles of different kinds of acid.

water vapor permeability test method factories

Scratch until you get underneath the top layer of gold. Expose a fresh layer of gold or any other metal underneath it. Nitric acid tests require you to scratch your piece of gold. If the gold has personal value to you or you plan on keeping it, take it to a professional jeweler instead of doing the test yourself. If the white metal you are testing is 14 karat white gold, the scratch mark on the stone will disappear in about 15 seconds. . I’ve tested all the metal’s with acid test before using it. It passed the acid test’s. And the 18 k gold acid test turns it white. But now that I’ve been add more gold to the white gold nugget the 22k acid . TL;DR: How to Acid Test Precious Metals. Acid testing is a vital technique for verifying the authenticity and purity of gold and silver, accessible to both professionals and enthusiasts.It involves using specific tools and safety .

With this test, the doctor puts small amounts of metal on your skin and covers the area with a patch. The patches are typically placed on the skin on a Monday, left on for 2 days then removed. An initial read by the physician is completed in the office at 48 hrs and 7 days after the initial placement. If you are allergic to the metal, you will . The Vinegar Test. Another form of acid test, using vinegar on gold is a simple, safe, and cost-effective method to test if it’s real. It also doesn’t require scratching the surface of an object. Using an eye dropper, place a .Patented in-line 3D imaging of scratch; Normal and tangential forces are standard and measured atop the sample; 3D Profiler and scratch data automatic correlation; Designed to quantify mechanical behaviors of bulk or coated surfaces from scratch. The SMT-5000 3D scratch tester measures scratch adhesion & cohesion, mar resistance, and hardness. Repeat the scratch test for each of your minerals. Once you've tested the first mineral, repeat the process for each of your mineral samples. If you're tracking the info on a graph, now you can look at results and write the minerals' hardness in the right-hand column. Advertisement. Part 2. Part 2 of 2: .

A metal spark test is useful for identifying the type of metal and in the case of steel, determining its relative carbon content. Spark tests use sparks given off when holding metal against a grinding wheel as a way of classifying iron and steel. . Hardness may be related to wear resistance since one measure is scratch resistance. The word . This video shows how you can use a metal file to know what type of metal you have. This is helpful when trying to differentiate between non magnetic metals.

material scratch resistance test

Never perform a scratch test on a finished stone. This can fracture or shatter the gem, even if tested on an inconspicuous area. Gem rough can be scratch tested, but caution is needed. Keep in mind that the rough may have incipient fractures that can’t be seen or internal stress that will open up easily to pressure. For these reasons, scratch . 1. Introduction. Scratch testing is a commonly used method to assess the coating adhesion strength both in academic research and industrial fields [1, 2], due to its practical setups and quasi-quantitative measurements [3].The related mechanism is also deemed as a basic theory in tribology, for its importance in studying tribological contact mechanisms. Appearance of new standards and modern devices for determining of adhesion characteristics of different coatings by scratch test creates new possibilities of those properties regulation in digital . 4. Scratch Test. One of the most foolproof methods for testing your gold jewelry is the ceramic scratch test. For this method, get an unglazed ceramic plate or piece of tiles and scrape a piece of gold across the surface. Real gold will leave a gold-colored marking, which other metals will just leave a black streak.

The synchronization of scratch data and 3D imaging ( Patent US 10,024,776 B2) is a unique and novel tool to study surface deformation and failures. Piezo actuator for precise down motion during scratch test. The best friction force sensitivity on the market owing to normal and tangential force sensors located in the head.Resistance to Scratch and Wear Method: To assess a coating’s resistance to scratch there are a number of different instruments that can be used: Pencil Hardness Tester - marking . Tester consists of a beveled disc indenting tool which is fitted into a stainless steel block exerting a constant test load of 500g (17.6oz).

how to do scratch testing

Pesquise entre fotografias de stock e imagens royalty-free de Beco Escuro na iStock. Encontre fotografias de stock de alta qualidade que não encontrará em nenhum outro lugar.

scratch test metal|what is scratch testing